Hilton Americas Houston Hotel

August 11, 2020

Mechanical Contractor Discovers Efficient Way to Convert 900 Bathtubs to Step-In Showers at Hilton Americas Houston Hotel

Unable to use previously specified, preformed shower pans, Way Engineering, Ltd switches to QuickDrain’s ShowerLine linear drain with tile-ready, pre-sloped PET shower pans to accommodate unexpected, plumbing rough-in configurations.

Problem

SUMMER 2020 | HOUSTON, TX — Conveniently located in the heart of downtown, Hilton Americas-Houston is connected to the George R. Brown Convention Center and steps away from a range of attractions, such as Discovery Green Park, Toyota Center and BBVA Compass Stadium.

Recently, the AAA Four Diamond hotel sought a cost-effective and efficient approach to convert 900 bathtubs into step-in showers for their elite guests, including star athletes and celebrities. Tasked with this challenge was mechanical contractor Way Engineering, Ltd, which had been involved in the original construction of the 24-story, state-of-the-art, convention hotel. Way Engineering is one of Houston’s largest mechanical contractors, specializing in commercial design-build work, including plumbing and piping. At first, the company specified preformed shower pans, unaware of the numerous jobsite irregularities and unexpected plumbing configurations its crews would soon face.

But once Way Engineering started renovations, the team encountered two significant challenges: (1) The existing plumbing rough-ins weren’t lining up with the drain opening in the preformed pan; and (2) post-tension cables were used in the hotel’s original construction. The latter meant that core-drilling to adjust the drains’ positioning would compromise the hotel’s structural integrity. So, Way Engineering had to find a versatile solution that would allow them to adapt to existing conditions.

In the meantime, one of the company’s senior estimators, Craig Burk, happened to discover QuickDrain USA at a local Houston ASPE event. Way Engineering had found its solution.

“We Realized How Versatile the System is After a Product-Knowledge Session Offered by one of QuickDrain’s Sales Representatives and Technical Application Specialists.”

Solution

“We realized how versatile the system is after a product-knowledge session offered by one of QuickDrain’s sales representatives and technical application specialists,” says Way Engineering’s Colton Bettison, who served as Project Manager for the plumbing scope of the project.

According to Bettison, previously specified, preformed pans required a six-inch modification of the floor for each shower. “It just wasn’t something we wanted to go through with. But, conversion-wise, the QuickDrainsystem saves more time and allows flexibility in terms of where the drain stub-ups are.” Bettison adds that the modular design of QuickDrain’s tub-to-shower conversions made it suitable to work with the existing conditions. “If we had done a preformed pan, there would’ve been more issues with material handling, leading to additional costs,” he says.

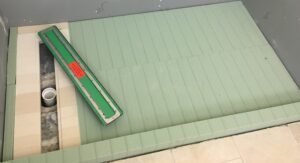

Ultimately, the Way Engineering team decided that QuickDrain’s tub-to-shower conversion kits and ShowerLine linear shower drain would be the best solution to convert 900 tubs to showers, maximizing productivity with minimal wasted effort or expense. ShowerLine’s integrated PVC drain body, combined with a pre-sloped PET shower panel and waterproofing sheet membrane, “Quickliner,” represents a total shower solution for effective and efficient drainage. The drain system features a fully sloped trough where water exits through either a vertical or a side waste outlet, making it easy to accommodate existing plumbing.

For the Hilton Americas applications, water exits through 2-inch, vertical outlets. Installers can select from among six decorative drain-cover designs to accent the overall design scheme of any bathroom. In this case, the Horizontal drain cover was deemed the best fit.

For the Hilton Americas applications, water exits through 2-inch, vertical outlets. Installers can select from among six decorative drain-cover designs to accent the overall design scheme of any bathroom. In this case, the Horizontal drain cover was deemed the best fit.

The general contractor for the project was DPR Construction, a national commercial contractor and construction manager.

DPR Construction requested an on-site model room training, during which a QuickDrain technical application specialist conducted a full installation to support DPR, as well as tile subcontractor Business Flooring Specialists and the plumber from Way Engineering.

The model room training was very straightforward, notes installation manager Jorge Garcia of Business Flooring Specialists. “QuickDrain trained as many as twenty crew members that one day. It’s a simple process and doing the model room ensures we pay attention to those smaller details, like where to apply QuickDrain’s Modified Urethane Sealant.”

Once the plumber made the mechanical drain connection, the tiling process proved much faster than what Garcia was used to, he says: “That’s because QuickDrain’s pre-sloped PET shower panels are prefabricated, and easily modified on-site.” The PET panels can be customized to fit nearly all shower enclosure sizes and conditions more efficiently and affordably than one-piece shower pans.

“Also, if we were to lay a mortar bed, we would have to let it dry, do the waterproofing and then come back the next day to do the flood test — taking up to three days to complete one shower,” explains Garcia, adding that the QuickDrain system removed an entire day out of the equation.

In a conventional, center-point drain shower, larger tiles are not ideal, according to Garcia. That’s because, when creating the four-way slope in the floor to the drain, the installer must cut the tiles. Using a linear drain eliminates that four-direction slope, creating new opportunities for tile design — in the case of the Hilton Americas Houston, complementing the existing larger-format tile on the bathroom walls.

Way Engineering’s Bettison says he heard no complaints regarding the drain connection. His plumber installed a new 2″ PVC riser to connect to QuickDrain’s PVC ShowerLine linear drain, with a permanent solvent weld connection.

QuickDrain’s tub-to-shower conversion kits eliminate the need to access plumbing from the bathroom below, which usually inconveniences guests and hurts hotel revenue. Bettison explains that, at the beginning of the project, there was a high occupancy in the hotel, and for many of the showers they installed, the rooms below remained in use. “The only thing we had to do was briefly go into the room below to replace a cast iron p-trap with a PVC p-trap,” he explains.

“It’s a Very Quiet Installation and Causes Minimum Disruption to Hotel Operations.”

Results

Installation manager Garcia says he woul recommend the QuickDrain system to other commercial flooring specialists. “It’s easy to install and you get a lot of productivity out of it.” Bettison agrees, adding: “It’s a very quiet installation and causes minimum disruption to hotel operations.

Ultimately, no two installations were precisely alike. Since the QuickDrain system easily adapts to jobsite conditions, it proved the most efficient way to convert 900 bathtubs at the Hilton Americas Houston into elegant, modern showers.